CHAINLINK FENCE

Chain link fence is one of the most popular choices of fence for both light residential to heavy commercial fence applications.

Chain link fence is one of the most practical styles of fence, relatively easy to install, and very cost effective. Mesh distribution uniformly surface smooth, nice appearance, easy to install. Various colors, good decorative effect.

The weaving is simple, artistic and practical.Chain link fences are easy to work, bright color, easy to maintain. Chain link netting are the first choose for beautifying the city environment.

SOL-SIGN Fencing has the latest automated machinery to manufacture Chain-Link fabric in accordance with BS 1722: part 2 for the industry in a wide range of heights and pitch sizes, which can be used for express ways, temporary and permanent sites, security fencing, sport courts and many other applications to suit your specific requirements.

Our Chain-Link fabric is made from guaranteed quality, and you can choose from a Heavy Galvanized wire (Class W10) or P.V.C. coated wire, in Beige or Green colors.

1) PVC Chain link Fence (Poly (Vinyl Chloride) (PVC) Coated

Fused and Adhered Poly (Vinyl Chloride) PVC Coated Steel Chain Link Fence Fabric

Basic Use:

Fused and adhered PVC coated fabric is a bonded vinyl, high strength galvanized steel chain link fence fabric for industrial, commercial and institutional applications. Fused and Adhered Fabric is contained in local, state and federal government specifications for use in prison, road, dock, airport, housing, forestry, and military use.

Composition and Material:

The galvanized steel core wire for producing extruded and adhered PVC coated steel chain link fence fabric is produced by cold-drawing good commercial grade steel rod into wire of the appropriate diameter. The steel rod from which the wire is drawn is produced by the open hearth, electric furnace or basic oxygen process. The galvanized coating is produced by passing the cleaned wire through a bath of molten zinc which conforms to ASTM B6. The fused and adhered PVC coating is produced by first applying a thermoset bonding agent to the galvanized core wire to which the PVC is bonded. A coating of PVC 0.006” (.15mm) - .010” (.25 mm) is then fusion bonded to the wire.

Standards:

ASTM B6 – Slab Zinc

ASTM F567 – Installation of Chain Link Fence

ASTM F668 – Poly (Vinyl Chloride) (PVC) and Other Organic Polymer-Coated Steel

Chain Link Fence Fabric, Class 2b

Federal Specification RR-F-191K/1E – Fencing, Wire, and Post Metal (Chain Link Fence Fabric), Type IV

AASHTO M-181 – Chain Link Fence, Type IV, Class B

Technical Data:

General:

Sol-Sign will supply samples and certification that all materials furnished comply with the appropriate specifications.

Chain Link Fence Fabric:

The vinyl coating is thermally bonded to a thermoset bonding layer over a galvanized steel wire. This process ensures a tightly adherent and impervious coating free of voids, as well as a smooth and lustrous surface appearance. Vinyl coating thickness, galvanized coating weight, and wire tensile strength conform to ASTMF668, Class 2b. Federal Specification RR-F-191/1E Type IV, and AASHTO M-181 Type IV, Class B, as shown in table 1. The wire is PVC coated before weaving and is free and flexible at all joints. Unless otherwise specified, fabric woven in 2” (50 mm) mesh, under 72” (1,830 mm) is knuckled at both selvages; fabric 72” (1,830 mm) high and over is knuckled at one selvage and twisted at the other. All fabrics woven into meshes under 2” (50 mm) have both selvages knuckled. Properties of PVC used for coating are in Table 3.

Wire Coating:

Only plasticized poly (vinyl chloride) (PVC) with a low temperature (-20 C; -4 C) plasticizer and no extenders or extraneous matter other than the necessary stabilizers and pigments, is used. The PVC coating resists attack from prolonged exposure to dilute solutions most common mineral acids, seawater, and dilute solutions of most salts and alkali. See Table II. The PVC coated wire shall pass the test for adhesion contained in ASTM F668 for Class 2b chain link fabric.

Installation:

Install fence in accordance with ASTM Practice 567. Handle all PVC coated material with care. If PVC coating is damaged during installation, contractor must replace or repair the material at own expense.

Maintenance:

Periodic inspection is recommended but no routine maintenance is required.

2) Chain link galvanized (Zinc Coated)

Product Name:

Zinc Coated (Galvanized) Steel Chain Link Fence Fabric.

Basic Use:

Zinc coated (galvanized) steel chain link fence fabric for industrial, commercial and institutional applications. Zinc coated fabric is contained in local, state and federal government specifications for use in prison, road, dock, airport, housing, forestry, and military use.

Composition and Material:

Zinc coated steel chain link fence fabric is produced by cold drawing good commercial grade steel rod into wire of the appropriate diameter. The steel rod from which the wire is drawn is produced by the open hearth, electric furnace or basic oxygen process.

The zinc coating may be applied before weaving into fabric (GBW) or after weaving into fabric (GAW). Galvanized before weaving (GBW) – The wire is cleaned, passed through a bath of molten zinc, and then woven into chain link fabric. Galvanized after weaving (GAW) - The uncoated wire is woven into chain link fence fabric of the appropriate height and mesh size. The coating is produced by passing the woven mesh through a continuous line which includes cleaning of the fabric. After cleaning, the fabric passes through a molten bath of zinc metal to produce the galvanized coating. Zinc used to produce the coating conforms to the requirements of ASTM specification B6.

Standards:

ASTM A392 Type 1 – Zinc-Coated Steel Chain Link Fence Fabric

ASTM F567 – Installation of Chain Link Fence

ASTM A817 – Metallic-Coated Wire for Use in Chain Link Fence

ASTM B6 – Zinc (Slab Zinc)

Federal Specification RR-F-191K/1F Type 1 Fencing, Wire and Post Metal (Chain-Link Fence)

AASHTO M-181 Chain Link Fence, Type 1

Technical Data:

General:

The manufacturer, if requested, will supply samples and certification that all materials furnished comply with the appropriate specifications.

Chain Link Fence Fabric:

The base metal of the chain link fence fabric is composed of commercial quality, medium carbon wire. The weight of the zinc coating, wire sizes with allowable variances, and wire breaking strength, as shown in Table 1, conform to ASTM A 817 for the wire size specified. The fabric is zinc coated after weaving or before weaving.

Coating Weight:

Zinc coated (galvanized) steel chain link fence fabric conforming to ASTM A 392 and other specifications referenced above is available in two coating classes with the following minimum weights:

Class1 – 1.2 oz/sq ft (366 g/ sq meter)

Class 2 – 2.0 oz/sq ft (610g/ sq meter)

GAW is available in either class. GBW is limited to Class 1 due to the limited availability of galvanized wire with a Class 2 coating. Fabric woven with mesh size less than 1” is only available in GBW.

Zinc Coated:

ASTM A392, Federal Specification RR-F191/1F Type 1, AASHTO M-181 Type 1

Sizes:

Galvanized fabric is available in mesh sizes from 3/8” to 2 3/8”, and in heights from 18” to 240”. Unless otherwise specified, chain link fence fabric woven with a 2” mesh and 60” or less in height is knuckled at both selvages. For fabrics 72” and taller, the selvage is knuckled at one edge and twisted at the other. All fabrics woven into mesh sizes under 2” are knuckled at both selvages.

Installation:

Install fence in accordance with ASTM Practice 567.

Maintenance:

Periodic inspection is recommended but no routine maintenance is required.

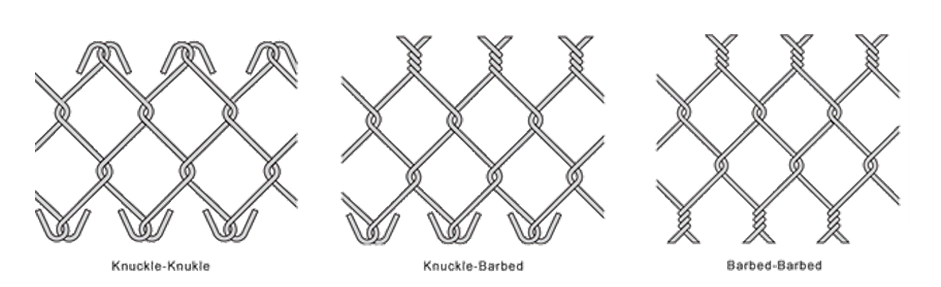

Three Ways of End Treatment

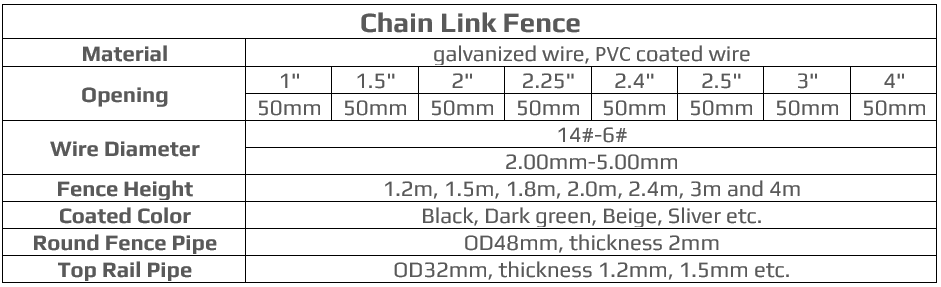

Parameters